JFLEX (JFC) was developed to provide a film that can add a highly-lustrous "black sheen" design, primarily intended for a variety of automobile exterior moldings such as side molding or bumper molding.

JFLEX can add a highly-lustrous black sheen that could not be achieved before with black molding made using extrusion molding or injection molding.

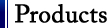

Note: The configuration of multiple film layers allows dramatic enhancement of shape-following when molded, design properties and durability; automotive, consumer electronics and other industries are expected to incorporate it in many molded plastic parts

Side molding / bumper molding / flush mount molding / belt molding / sash molding / center pillar molding / fender arch molding / grill molding / door edge molding and other automotive exterior molding / plastic molded parts for home appliances and other applications

- Hot press can be used for terminal treatment of extrusion molding

- Vacuum forming and injection molding can be used

- Ideal for continuous extrusion forming due to high-tensile film material (PET, etc.) based protect film layers

- Superior transparency of the surface layer, providing high-quality brightness, design properties, weather resistance and chemical resistance

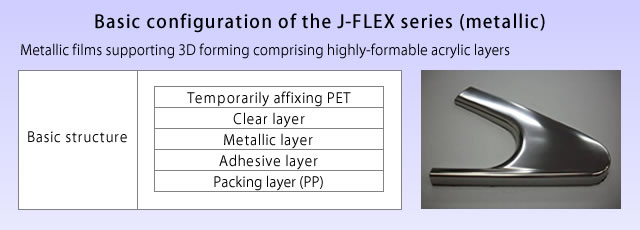

- Regarding film structure, the backing resin is colored black so that one layer has the function of both coloring and backing, providing a highly-lustrous black sheen.

- PVC and PP types are provided for the backing layer to match the type of molded resin*

Note: It is possible to accommodate multilayer application to match other resin types.